There are several reasons to consider the type of infill used in your 3D printing projects. The infill is a crucial part of the process because it gives the printed model strength. It also provides the framework to support the model's high interior angles. For example, the cube infill pattern improves the floating ability of a printed model. It is important to experiment with different types of infill to find out which one works best for your design and needs.

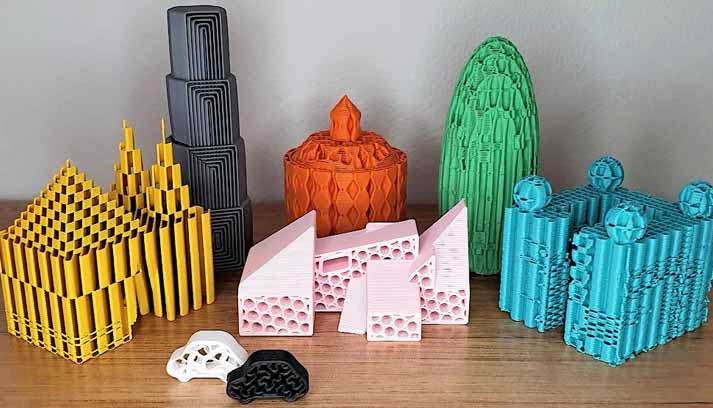

Different Types of Infill

There are many different types of infill, each with its own strengths and weaknesses. There are some benefits and disadvantages to each. For example, the type of infill you choose can affect the final product's strength and durability. There are two primary types of infill: concentric and hexagonal. The former is suitable for simple, thin objects, while the latter is suitable for complex and multi-dimensional models.

Concentric Infill

Concentric infill is best suited for non-functional parts, like display prototypes or presentation models. It reduces the volume of materials used and is ideal for flexible models. Its main disadvantage is that it requires too much material. While the latter is useful for functional parts, its main advantage is the strength and stiffness it adds. It is the best choice for high-end 3D printing applications.

Rectilinear Infill

For practical reasons, a rectilinear infill is the most suitable option. It uses two-dimensional triangles in order to fill a layer. This type is the best choice for flat, nonfunctional models. Because it requires less material, it is also effective for functional parts. Its downsides include high material consumption and an extremely slow print speed. If you want to avoid this, you can choose a hexagonal infill.

Choose the Right Type of Infill

When you print a model, you should decide the type of infill that is right for your design. If your design is flat, a ten to twenty percent infill is enough. For a larger model, a ten to twenty percent infiltrated layer is the most useful. It is also the cheapest option. However, it is essential to consider the strength of the infill before printing your 3D models.

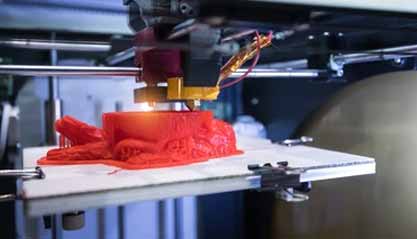

Material Considerations for 3D Printing

While infill density is a key feature for 3D printing, it is important to consider the material you are using. If you are printing a functional object, a high-density infill is necessary. It will make the model more durable and reduce the risk of cracks. There are a few types of infill. A concentric infill is not always the best choice.

Conclusion:

The type of infill in 3D printing is essential to the final result. The type of infill you choose will determine the strength and feel of your finished product. Infill is an important part of a 3D print. For example, if you have an empty space in the middle of your print, you can print the top layer without infill. A high-quality infill pattern will be strong, while a low-density one will not have a hollow interior.